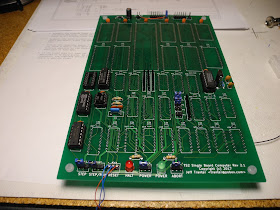

After almost three months of waiting, my printed circuit boards arrived! I had just about given up, and was in the process of filing a PayPal dispute when they finally showed up.

These were manufactured by EasyEDA.com. They were very low-cost and the boards are high quality double-sided, plated through, solder masked and silk screened. I found it very easy to upload the design files from kicad to EasyEDA.com.

I had to order a minimum of five (I actually received six) but the cost was lower than most other vendors for one board.

This was the first PCB I have ever layed out. I expected a few errors, or possibly something that would make the boards unusable. It turned out I did have a few issues. Somehow a few power connections were omitted in the layout. I'm not yet sure if this was my fault or a bug in Kicad or the router software. I did make one glaring error that I had overlooked on the schematics - the UDS* and LDS* signals to the 68000 were reversed. When I wirewrapped my prototype I had connected them properly.

As compared to the wirewrap version that took the better part of a week (part time) to wire up, assembling the PCB took only a couple of hours, and much of that was making some sockets out of smaller sockets and carefully checking that the right ICs got installed.

I had to add a few "bodge" wires to correct the missing and incorrect wiring. After that, the board is working 100%. It looks very nice. I layed it out so that the switches and LEDs could be mounted externally from the board in a case. I may install it in a case once I find a suitable enclosure Or I may again just mount a piece of plexiglass over the top.

At the moment I have no plans to make more boards, and I only have enough parts for one (I had to cannibalize the parts from the wirewrap prototype).

I will shortly update the design to address the layout issues and make a set of files for a rev 2.1.1.

All in all I am quite happy with my first PCB layout. When I started with kicad I didn't think I would bother beyond wirewrapping a board. It is very gratifying to see a professionally looking board that has my name on it.

Jeff,

ReplyDeleteThis project is great, I have been reading your posts with great interest.

I have a 2nd Edition copy of the Clements book and have intended building something based around the TS2 for quite a while now but just can't face doing all that wire wrapping.

Your PCB design looks just the part and I have most of the IC's so I was considering getting a few boards made using your design.

I notice the latest version in the Github repo is 2.1 so I assume that doesn't have the corrections and would thus require the 'bodge' wires?

Are you close to releasing 2.1.1 which as I understand it will have the fixes?

If I am going to get some boards made it would of course make sense for me to wait if the newer version is imminent.

Either way its a wonderful project so thank you for taking the time to write blog entries showing the progress.

Lynton

I noticed that your github for V2.1 includes comments that they were updated for V2.1.1 and the new gerber files include the V2.1.1 designation on them.

ReplyDeleteI am ALMOST ready to make my own PCB's and try building one of these myself.

I grew up with the Z-80 based machines, but was always interested in the 680X0 family.

Thank you for your work on this project. I'll let you know if I ever get past the "want-to" stage.

Cheers,

John Gay

Greetings

ReplyDeleteI am interested in constructing your 68k single board computer . I wonder if

you have any of the PCB's left as I would like to purchase one .

Looking forward to your reply

Regards

Philip

Electrical Engineering Services Company

ReplyDeleteelectrical engineering company

Electronic Product Design

electrical engineering firms

Circuit Design Services

Reverse Engineering Services

PCB layout Services

pcb design

PCB Prototype Manufacturer

Product Engineering

Product Design and Development

PCB Design

Prototype Company

prototyping company

wireless rf design

electronic circuit design service

Electronic product development, electronic engineering services, electronic design, systems engineering,electrical engineering services, Product Architecture, new product development, pcb layout,pcb design, circuit design, fpga design

I finally pulled the trigger and ordered a set of V2.1.1 boards from JLCPCB.

ReplyDeleteNow to start getting the parts to fill the board and see how it works.

Cheers,

John Gay

Electrical contractors play a vital role in turnkey hospitality projects, providing essential services to ensure the successful completion of these projects. We are the Electrical Contractors for Turnkey Hospitality Projects & provide design, installation, and maintenance of electrical systems, including lighting, power, and data systems. With our expertise in electrical engineering and construction, cadence electrical helps ensure the safety and functionality of hotels, resorts, and other hospitality facilities. From pre-construction planning to final inspection, we as electrical contractors work closely with project teams to deliver high-quality, cost-effective solutions for hospitality projects.

ReplyDeleteThank you sharing for this great post.Find Reliable PCB Circuit Boards for All Electronic Needs

ReplyDeleteGreat project! It’s impressive to see a single-board computer built around the 68000 with such attention to detail. The breakdown of your design and debugging process is super helpful for enthusiasts diving into retro computing. For anyone planning similar hardware projects, exploring reliable PCB designing services can really streamline the process and ensure precision. Thanks for sharing your journey!

ReplyDelete